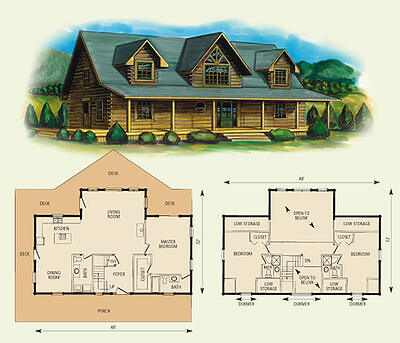

We offer over 75 predesigned log home floor plans.

Find Your Dream Home

1-866-LOG-HOME

We offer over 75 predesigned log home floor plans.

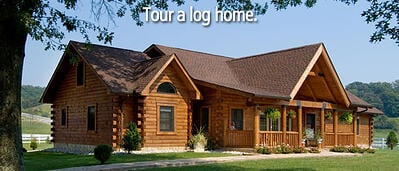

Find Your Dream HomeDo you dream of blue skies and mountain air? Are you looking for a home that is far removed from city life? An Appalachian Log Structures’ cabin may be just what you’ve been searching for. Our log ...

Read the Full Post

Although Appalachian Log Structures offers over 60 pre-designed log home floor plans, the majority ...

Building your dream log home is likely one of the largest investments you will make in your ...

Over the centuries log homes have come a long way. The resurgence in log home construction came in ...

A lot has been written about the energy efficiency of log homes. When discussing this topic with ...

Most people think of Appalachian Log Structures as a producer of log cabin homes, but we're SO much ...

Remember the good old days - when you would put on your home made or store bought costume and walk ...

When speaking with folks about their dream log cabin home the 3 features of the home that they are ...

Not everyone has the same wants and needs when deciding on what size log home to build. It is a ...

Over the past 20 years I've been blessed to assist hundreds of people in realizing their dream of ...

Here is an article from the Log Homes Council website that reviews the GREEN advantages of log home ...

How much does a borate pressure treated log home really save you? To answer that question you have ...

Looking back 22 years ago, my wife and I were putting the finishing touches on our log home and ...

Learn about the process of investing in, building, and maintaining a log home by watching our on-demand video seminar.

© 2024 Appalachian Log Structures, Inc. All rights reserved.